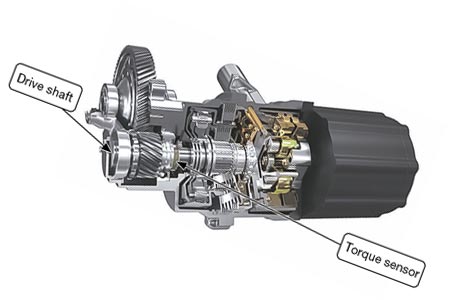

NSK Ltd. has developed a non-contact torque sensor that measures drive shaft torque in real time, the first in the world with this capability.

The sensor can increase fuel economy, improve ride comfort and safety, and expand a world of new possibilities across CASE (Connected, Autonomous, Shared & Services, Electric).

The sensor uses magnetic fields to detect torque by measuring minute twisting of the drive shaft that occurs naturally as it is rotated by the motor. Conventional torque sensors have been too complicated or expensive for wide scale use. NSK created a simple structure in a compact form, ideal for mass production and easy adoption by automakers. NSK estimates 6 billion yen in yearly sales by 2030. DEVELOPMENT BACKGROUND:

DEVELOPMENT BACKGROUND:

The drive shaft is a key component that transmits engine or motor power to the wheels. Measuring torque at the drive shaft provides vital information that can be used to increase fuel economy, improve comfort and safety, reduce environmental impact, and even detect abnormalities or malfunctions in the vehicle.

PRODUCT FEATURES

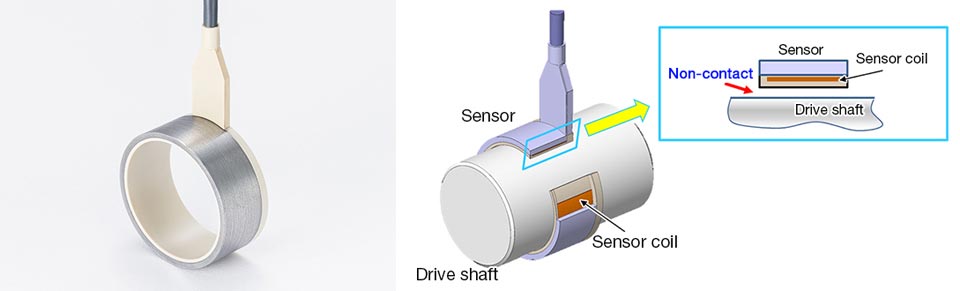

Non-Contact Sensor

A simple form factor ideal for mass production.

High reliability due to no friction between the sensor and the shaft.

Compact:

Proprietary technologies reduce the width of the unit by half and enhance sensitivity.

Ease of Adoption:

Sensor requires no grooves, coatings, or other special processing of the shaft.

CUSTOMER BENEFITS:

1. Better Fuel Economy

For EVs with a two-speed transmission, NSK's torque sensor can provide shock-free gear shifting, enabling the use of a larger step ratio to deliver 7% increased fuel economy*1. In CVT systems, the sensor can help adjust the hydraulic clamping force on the belt to the minimum required, reducing transmission losses for a 1.05% increase in fuel economy*2.

2. Increased Comfort

The torque sensor can deliver a smoother ride through advanced control that softens fluctuations in torque when changing gears and accelerating/decelerating.

3. Identify Abnormalities

Continuous torque monitoring, can help predict and identify abnormalities in the vehicle at an early stage before they develop into larger problems.

4. Connected

As always-online vehicles become the norm, the data gathered by the sensor can be used to identify the state of nearby vehicles, and can be shared and analyzed to identify collective road usage patterns and deliver new value to society.

NSK is expanding its horizons with new connected products – such as this torque sensor – that can contribute to the further evolution of mobility on a global basis.

About NSK:

NSK began its journey manufacturing the first bearings in Japan in 1916, and has since developed into a global organization researching, designing, and manufacturing Motion & Control™ solutions essential for mobility and industrial applications. NSK is the top supplier of bearings in Japan and is the third largest supplier in the world by market share.

For further details visit NSK Americas: https://www.nskamericas.com/en.html